|

29. Image analysis of the internal structure of paper and wood fibre based composite materials in 3D images

Maria Axelsson, Filip Malmberg, Erik Wernersson, Anders Brun, Stina Svensson, Joakim Lindblad, Cris Luengo, Gunilla Borgefors, Catherine Östlund

Partners: Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway; STFI-Packforsk, Stockholm; Dept. of Fibre and Polymer Technology, KTH, Stockholm; Dept. of Physics, University of Jyväskylä (UJ), Finland; SINTEF Materials and Chemistry, Norway; Risø National Laboratory, Technical University of Denmark

Funding: S-faculty, SLU; WoodWisdom-Net

Period: 0406-

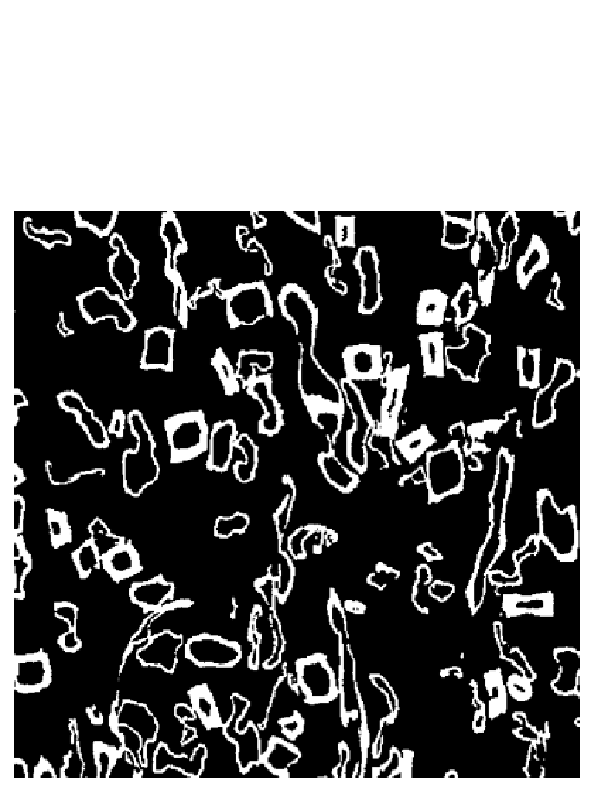

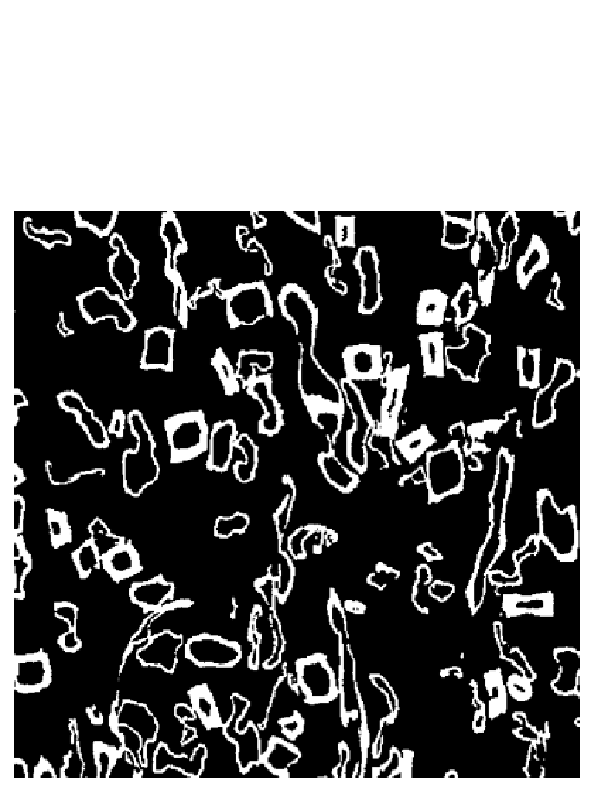

Abstract: The internal structure of paper is important to study since many material properties correspond directly to the properties of single fibres and their interaction in the fibre network. How single fibres in paper bond and how this effects paper quality is not fully understood since most structure analysis of paper has been performed in cross sectional two dimensional (2D) images and paper is a complex three dimensional (3D) structure, see Fig. 14 (top).

Another application for wood-fibres

that has recently gained interest is wood polymer composite

materials. The properties of these materials do not only depend on the

structure of the fibre network, but also on interaction between the

fibres and the polymer matrix surrounding the fibres. Advances in

imaging technology has made it possible to acquire 3D images of paper

and wood polymer composite materials. In this project, image analysis

methods for characterising the 3D material structure in such images

are developed. The detailed knowledge of the material structure

attainable with these methods is useful for improving material

properties and for developing new materials.

An example slice from a binarised volume and a surface

rendering of a sample of a composite material image with X-ray

microtomography are shown in Fig. 14 (top).

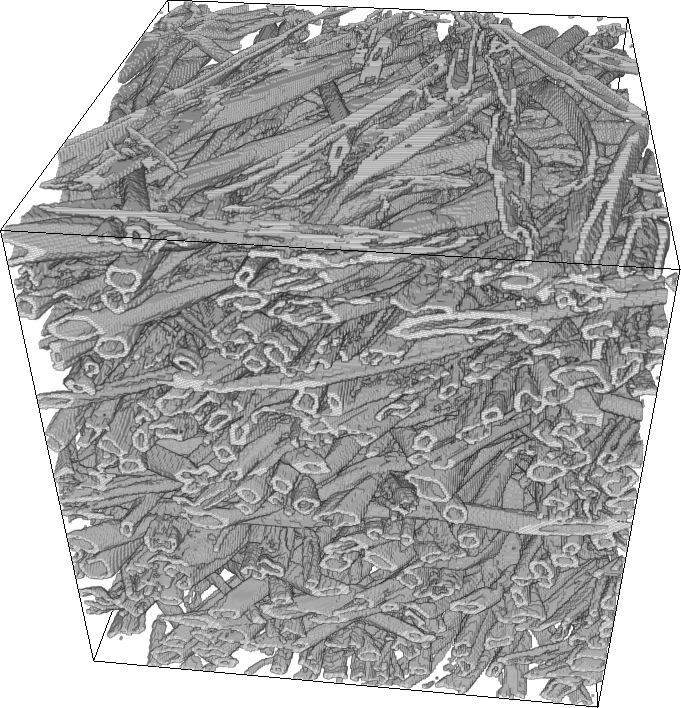

The project objective is to achieve a complete segmentation of

individual fibres and pores in volume images of the material. Given

such a segmentation, any measurement of the internal structure is

available. Measurements on individual fibres and the structural

arrangement of fibres can then be related to macroscopical material

properties. A tracking method to segment fibres was recently developed

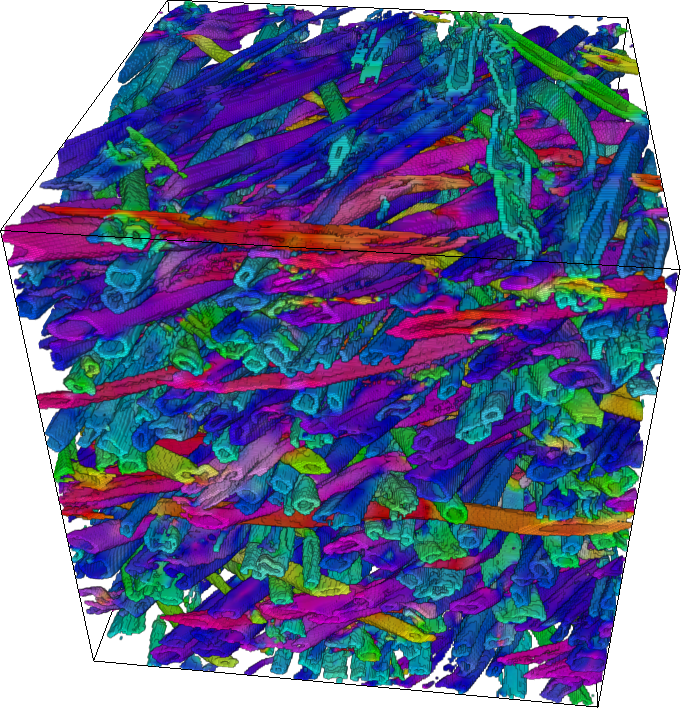

and a result can be seen in Fig. 14 (bottom).

Other methods for measuring properties of the material,

that do not require a complete segmentation of the samples, are also

investigated.

In this project, different volume images of paper and composite

materials are available for the studies. This includes one volume

created from a series of 2D scanning electron microscopy (SEM) images

at StoraEnso in Falun and X-ray microtomography volume images of paper

and composite samples imaged at the European Radiation Synchrotron

Facility (ESRF) in Grenoble, France and at the Paul Scherrer Institut

(PSI) in Villigen, Switzerland. Furthermore, methods for creating other

sample volume images are investigated.

During 2008, the project has resulted in a number of publications. A licentiate thesis on binarisation and segmentation of e.g. X-ray microtomography images and fibre-fibre contact measurements was presented. A new method for estimating 3D fibre orientation in volume image data, which provides an estimate of the fibre orientation in each voxel, was presented at the International Conference on Pattern Recognition (ICPR). A volume rendering of a wood fibre composite is shown to the left in Fig. 15 and to the right, the estimated orientation in the material is shown using pseudo colour that correspond to the orientation vector. The porous structure of fibre based materials was also investigated during the year. A study of the pore structure of newsprints was published in Journal of Pulp and Paper Science in collaboration with Norwegian Pulp and Paper Research Institute (PFI), Trondheim, Norway. In a cooperation with University of Jyväskylä different image analysis methods to simulate intrusion and extrusion processes of Mercury Intrusion Porosimetry (MIP) in porous material were compared and presented at the Progress in Paper Physics Seminar.

|

|

32. Quantification of the quality of wood fibres

Bettina Selig, Cris Luengo, Gunilla Borgefors

Partners: Dept. of Forest Products, SLU

Funding: S-faculty, SLU

Period: 0709-

Abstract: Wood fibre quality is important for many uses of this raw material. The quality can be tested by various microscopy methods.

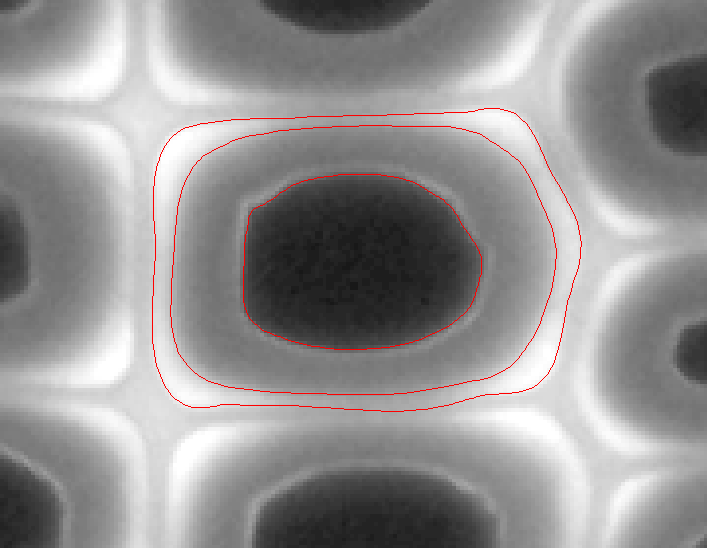

High lignification of the wood cells has effects on their mechanical properties which is especially important in paper production. Before these effects can be studied the degree of lignification has to be estimated. In auto flourescence light microscopy images of fibre cross-sections, the substance lignin is made visible, as it emit more light than other parts of the cell wall. The goal here is to develop an automatic method to detect and measure highly lignified areas and relate them to the area of the whole cell wall. The task is much complicated by the fact that edges are notoriously fuzzy in flourescence images, but the problem is now solved for single cells, see see Fig. 16.

In a second part of the project, the damage of single fibres (breaks, cracks, distortions etc.) shall be characterized and classified. And in a third part the thickness of the middle lamella shall be estimated. For both problems polarized light microscopy images will be applied.

|